Services

What I do?

#1

IMDS Consulting

#2

PPAP Documents Preparation

7 Step Manufacturing Process Development

Best practice in developing manufacturing process.

Documenting your process

Process Flow diagrams, PFMEA, Control Plans

MSA

“Statistical studies shall be conducted to analyze the variation present in the results of each type of measuring and test equipment system. This requirement shall apply to measurement systems referenced in the control plan. The analytical methods and acceptance criteria used shall conform to those in customer reference manuals on measurement systems analysis. Other analytical methods of acceptance criteria may be used if approved by the customer”

#3

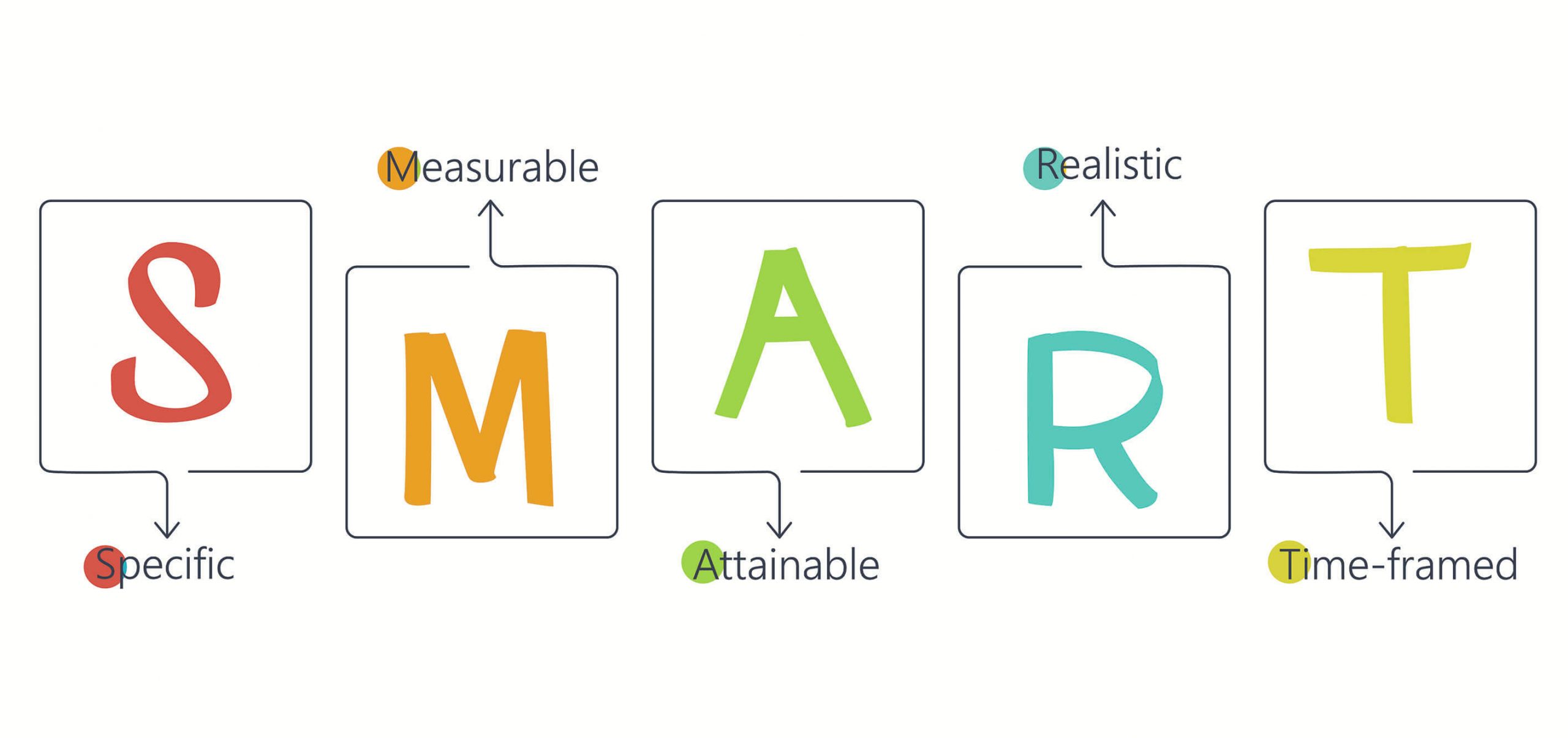

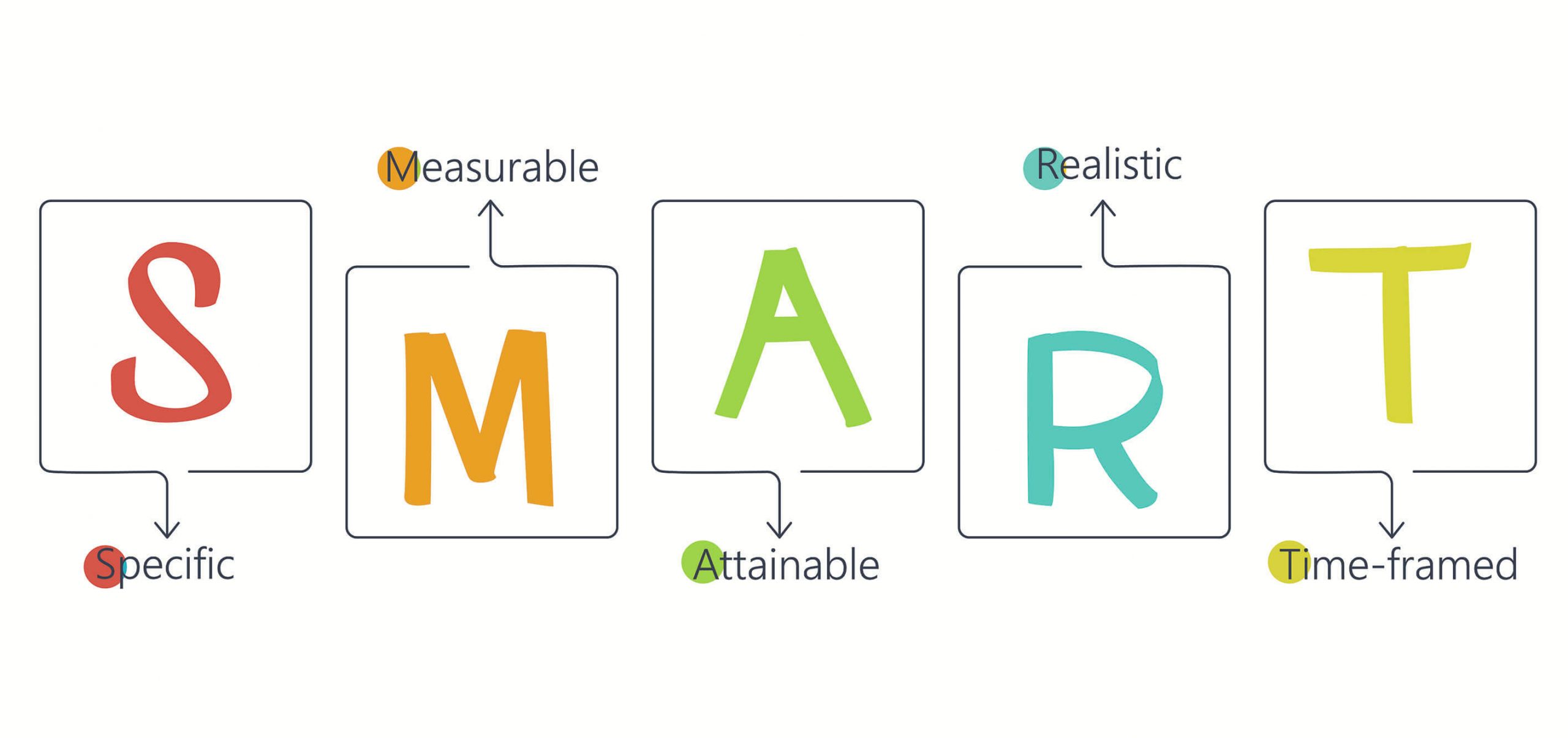

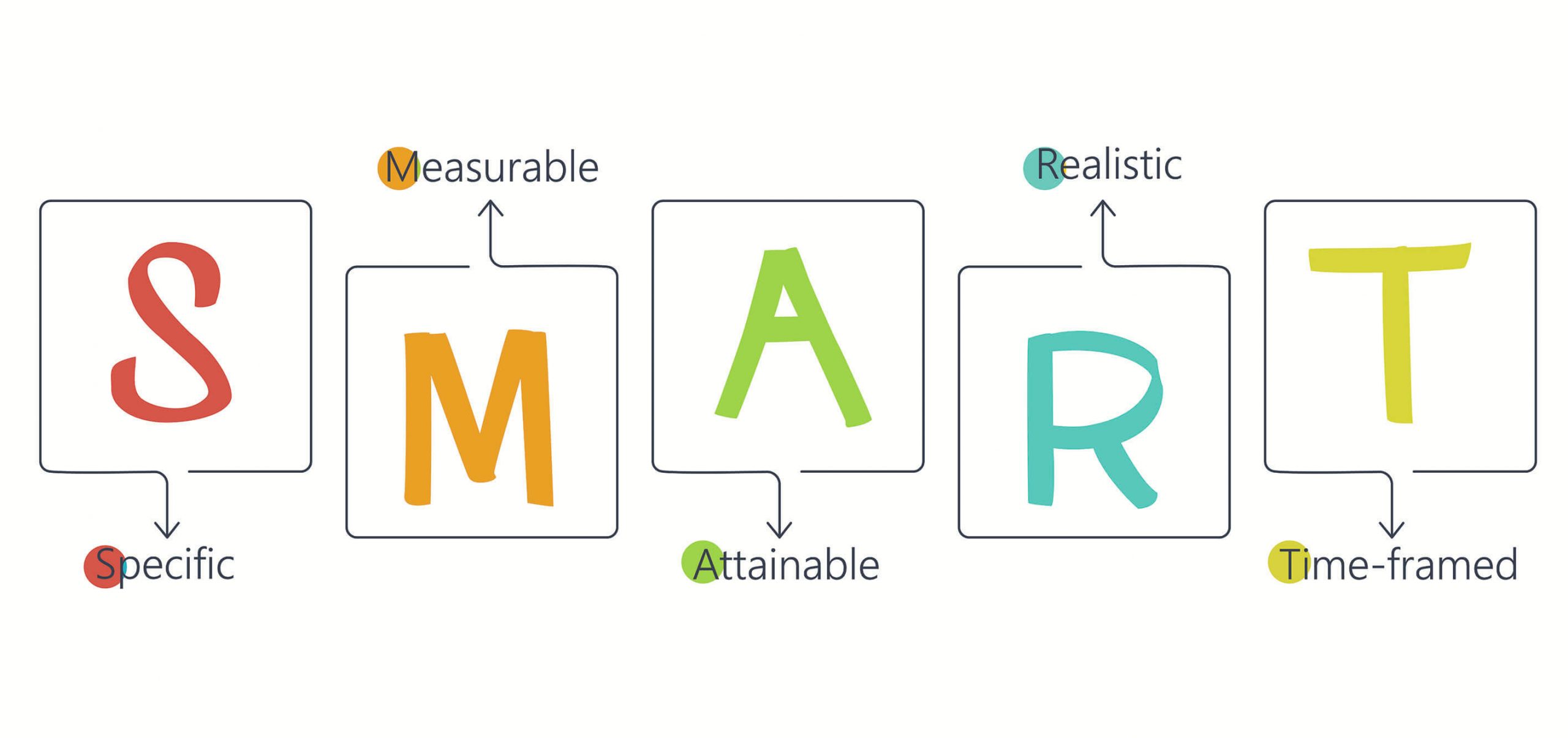

Supplier Development Programe - Project SMART

Project SMART targets to drive down GII and develop suppliers to ensure process controls are in place and their final inspections are robust enough to prevent Clients to carrying out verification processes and faulty parts getting to our customers. Below you can find some benefits of this programme.

Have "The right amount” of suppliers.

- Quality & delivery you can rely on – min ISO9001 for products and services incorporated into your own products.

- Controlled by management of suppliers, not by inspection (“Ship to stock”).

- Standardisation of components across core product range (“parts bin” / catalogue)

- Maximise economies of scale with core supply base (“a lot from a few”).

- Receipt of final parts from suppliers (they control all sub-processes).

Identify and manage critical suppliers based on risk

- Financially sound

- Risk mitigation / contingency plan in place

- Close relationships – owned by purchasing

- Work with suppliers ASAP in projects – provide complete and full specification

- Supplier selection handled by purchasing

- Supplier performance managed by purchasing (KPI’s and corrective actions)

- Two-way flow of information from suppliers (Utilise their knowledge base).

- Involve internal purchasing in initial project scoping/planning

Design for manufacture

- Re-prioritise selection criteria

- Quality and delivery at the right price

#4

Internal/ Supplier Audits

ISO 9001

- An effective Internal Audit Program is essential to the success of your Management System.

- Use it as a tool to maintain, adjust and improve the Management System. It is one of the mandatory requirements of the standard.

- Without auditing, there is no assurance that the Management System is effective and efficient. The value of a Management System implementation is questionable when there is no objective evidence that best practices are implemented, conformance is constant, and corrective actions are effective.

- Without auditing, the initial ROI of implementation is likely to diminish significantly.

this is why

We should work together

Save Time

Focus on core business

Right first time

Improve Customer Service

Simplify projects

Start new projects quicker

Control Cost

No need for expensive training

reduce the risk

Meet regulatory obligations

Expertise

Improve quality

Free Estimation

Request a quote

Please describe your requirements and products/ materials involved.